Home Decor and Building Products

Industrial Inkjet technology is making a dramatic impact on the Home Décor and Building products market. This market was traditionally serviced largely by gravure printing and in some instances silk screen. These technologies required large print runs, extensive set up time and generally are suited for a fairly simplistic flat design. Inkjet technology has enabled these industries to supply higher resolution, photo quality imagery while massively reducing global inventories. Further this technology allows for a dramatic capability of mass customization with just in time inventory. For example printing photo realistic quality wood grains allows the masses to afford even the most exotic woods. Wall paper can now be printed with custom designs or colors that compliment your furniture and flooring.

Ceramic Decorative Printing

Printing decorative tile with Industrial UV ink allows for graphical images on non traffic bearing tile.

Decor Paper Printing

Industrial Inkjet printing to Décor paper used in laminate flooring has revolutionized composite flooring. Inkjet technology can print photorealistic images of the most rare hardwoods known without repeats and on-demand. When laminated with extremely hard overlaminates you get the best of all worlds with a scratch resistant, dent proof beautiful floor.

Decorative Etching

Printing decorative etching with UV ink allows for a matte effect and provides a degree of privacy while allowing full and effective use of natural lighting. With this process you can control properties such as density, opacity, and even color which will control the translucency and light transmission, and create a striking and very natural ambience in building interiors.Our Clear Etch inks deliver a semi-transparent frosted appearance to ensuring a high degree of privacy. Our Digital White Etch ink provides a pleasant etched appearance without hampering the flow of ambient light.

Finished Glass Printing

Digitally printed finished glass with UV inkjet ink allows designers to add incredible graphics to glass used in office buildings, cubicles and even churches. Molecule also has a clear UV curable ink that mimics glass etching allowing companies to create a unique etched glass look in a quick and easy process of printing.

Frit Based Fired Printing

Frit is a ceramic composition made generally through a chemical reaction of silica, an alkali, metals and lime content. These reactions create the series of colored frit which are then ground down to sub micron size and integrated into inkjet ink formulations. The inks are printed onto glass or cermic tiles and then fired at high temeratures 800-1200C. There are some projects currently for making "low temperature cure" frit that may cure in the 300C range. Once fired the printed ink melts into a very stable ceramic glaze.

Furniture Edge Band Printing

Digitally printed finished glass with UV inkjet ink allows designers to add incredible graphics to glass used in office buildings, cubicles and even churches. Molecule also has a clear UV curable ink that mimics glass etching allowing companies to create a unique etched glass look in a quick and easy process of printing.

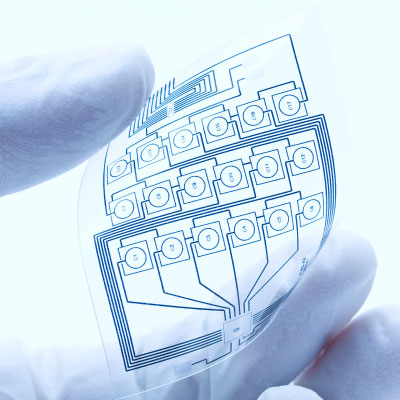

Glass Laminate Film Printing

One method of digitally printing glass is to print to a polyvinyl butyral (PVB) laminant which is sandwiched between two sheets of glass. This process requires a specialty formulation which boasts automotive grade pigments that will give long durability to both indoor and outdoor applications.

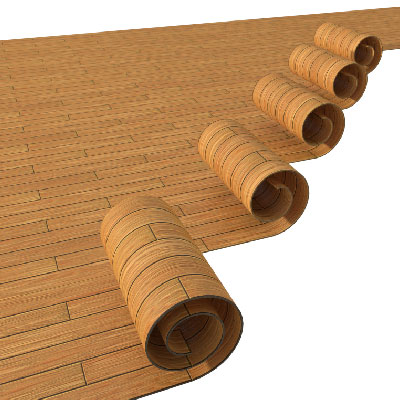

Laminate Film Printing

Printing directly to the laminate melamine film layer creates a very durable and efficient final product. Whether you need to print photo realistic exotic woods, expensive marbles or tile patterns, printing directly to the laminate film is a Foil effective and high quality method of creating flooring.

Print During Glass Manufacturing

Specialty inkjet inks which utilize "frit" pigmentation are used in the printing process during the manufacturing of the glass. The frit is the same pigmentations (silica based) that are used when firing tile or pottery. When printed it has a whitish look but, after firing the frit silica melts into the glass making a monolithic layer of colored glass.

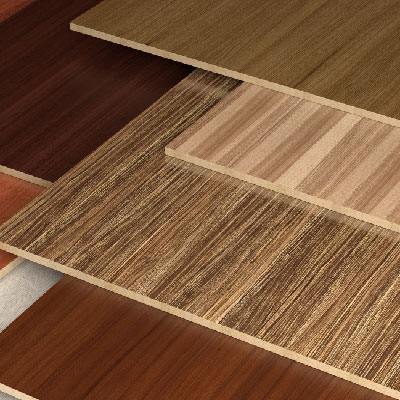

Rigid Board Printing

Medium-Density Fiberboard (MDF), is a material extensively used for the manufacture of indoor furniture. MDF is inexpensive, hard-wearing, and is ideal for furniture making. Much of the lower end furniture and system cupboards available on the market use MDF or Melamine Faced Chipboard (MFC) to manufacture their furniture products, for example, IKEA, Green Furniture, ORDER system furniture, and other system furniture retailers.Large flatbed UV inkjet printers have become extremely common for printing MDF to meet the low cost demands for home furnishings.

Vinyl Flooring

Industrial Inkjet printing vinyl flooring for forward looking flooring manufacturers has allowed them to drastically reduce set up times, reduce or eliminate set up costs and dramatically reduce inventory. The technology is also allowing them to print just in time and even provide customers with additional material which matches the production run if they did not order enough. Whether printing 1' wide tiles or 16 foot wide vinyl sheets industrial inkjet technology is able to meet the demands. Molecule has worked with clients to match inkjet inks to their traditional gravure ink. This can drastically reduce metamerism and allow them to print prototypes on a digital machine and scale up on their gravure equiment. It is also possible to print chemical relief coatings digitally to allow the embassing of your product to match the grain or texture of your grapgical image.